High-precision micro-power digital temperature sensor (temperature-code converter) with RS-485 interface

Main characteristics

Primary converter |

platinum resistance thermometer Pt1000 |

Measurement range |

-40..+90 °C; -40..+180 °C; |

Accuracy over the entire measurement range |

< ±0,1; ±0,05;±0,02; ±0,01 °C |

Thermal inertia index |

< 20 sec |

Wiring diagram |

4-wire connection with shielded signal cable (2-wire RS-485 line plus common ground wire connected to the shield and power wire) |

Calibration standard |

ITS-90 |

Supply voltage |

2.7..5.5 V |

Maximum pulse current consumption in active mode |

< 1.5 mA |

Standby consumption current |

< 4 uA |

Average current consumption in the continious reading with a period of 30 sec |

< 12 uA |

Average current consumption in standby mode with continuous polling of other RS‑485 nodes |

< 25 uA |

Active mode consumption current (if you have an isolated RS-485) |

< 2 mA |

Standby consumption current (with isolated RS-485) |

< 500 uA |

Current consumption (with active device heating) |

< 120 mA |

Ambient temperature |

-40..+70 °C |

Start time after power up |

< 100 msec |

Measurement speed |

up to 10 SPS |

Material of protective reinforcement |

stainless steel |

Converter housing material |

aluminium alloy |

Immunity to dust and moisture |

IP-65, IP-67 |

Length of communication line |

< 1500m (9600bps speed) |

Data transfer rate (with an increase in speed of more than 9600bps (up to 3Mbps), the converter goes out of micro-power mode) |

9600, 4800, 2400, 1200, 600bps |

The number of devices on the RS-485 bus |

up to 247 |

High-precision measuring device designed for remote automatic data collection using a standard communication protocol without special software.

Power supply of the device is negligible and is carried out directly from the RS-485 bus. With a maximum network load (continuous serial polling of 247 devices), the total consumption in the RS-485 power supply circuit does not exceed 7 mA (for non-isolated RS-485 interface).

Isolated or non-isolated RS-485 interface. Communication protocol Modbus RTU (optionally it is possible to connect using other protocols based on the RS-485 interface). Up to 247 sensors in the network.

High noise immunity.

High reliability and long-term stability.

Designed for mass production.

Design features

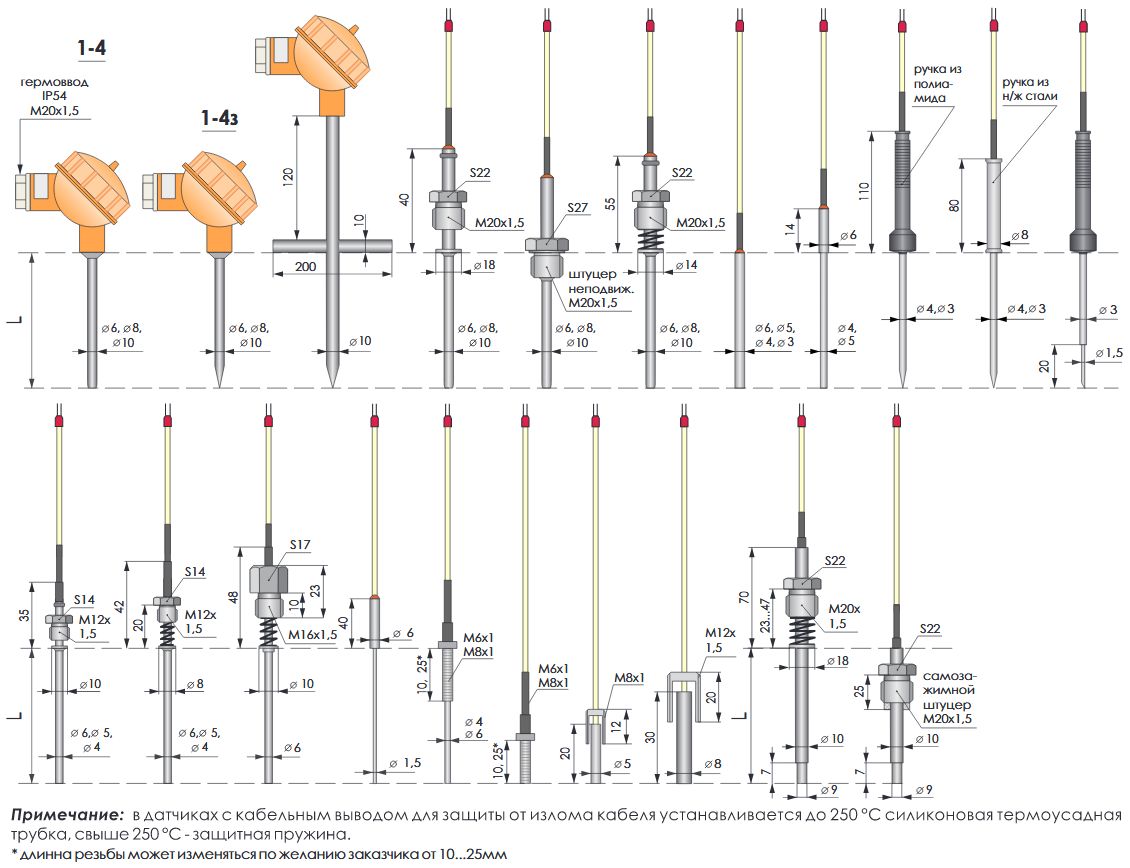

STV-T-485 consists of a primary sensor - (Pt1000) in a cylindrical protective casing made of stainless steel of the required length and a processing and conversion unit, placed in a sealed aluminum alloy case with dimensions of 35x40x50mm and equipped with an 8-pin POLSUN connector, connected by a 300mm heat-resistant silicone cable.

Possible versions of the thermometer: sleeve, sleeveless, to the surface.

In case of a sleeveless design, the required length of the primary sensor is selected from the range: 25, 32, 50, 80 mm.

When the sleeve version is from a number: 32, 50, 80, 120, 160, 200, 250, 300, 440, 530mm.

Interface and system integration features

The device combines a sensor (sensing element) and a transducer, which processes the readings from the sensor and transmits them via the RS-485 interface.

A platinum resistance thermocouple is used as the primary temperature sensor in the probe. The on-demand electronic unit converts the thermal resistance parameter into digital code packets in the standard EIA/TIA RS-485. This makes it possible to build distributed control systems and process control systems without the use of additional converters using the standard network digital exchange protocol ModBUS RTU (www.modbus.org). The electronic unit includes an ADC and a microcontroller, in which an algorithm for converting electrical resistance into a digital code is programmed. This algorithm includes a procedure for calibrating a platinum resistance thermometer according to ITS-90, correction of thermometer readings based on calibration results, as well as additional service functions.

At the request of the network master (register reading procedure), the results of temperature measurements are given.

With one master device (PC or PLC) and one communication line, it is possible to take readings from many sensors in the network (up to 247), by sequential polling.

Areas of use

Machine building and metalworking

Power engineering

Production of technological equipment by industry

cold production (refrigeration and air conditioning)

heat production (heat engines and air conditioning)

heating networks

heat exchange equipment

Construction and municipal engineering

Agricultural engineering

Oil and gas engineering

oil / gas heaters

equipment for oil refining

gas and oil transportation equipment

Chemical engineering

Timber industrial engineering

Automotive industry

Machine tool

Food industry equipment

Industry of household appliances and machines

Instrumentation

heat and water meters

gas meters and gas volume correctors

Radio and electronics industry

Electrical industry

Chemical and petrochemical industry

petrochemistry

agrochemistry

polymers and elastomers

pharmaceutical chemistry

perfumes and cosmetics

Fuel industry

gas industry

oil industry

Pulp and paper industry

Building materials industry

Food industry

soft drinks industry

wine industry

confectionery industry

canning industry

pasta industry

oil and fat industry

dairy industry

milling industry

meat industry

brewing industry

fruit and vegetable industry

poultry industry

fish industry

sugar industry

alcohol industry

tobacco industry

Medical industry